A few years ago, the company set up its own in-house oil mill, comprising an olive defoliator and washer, knife crusher, vertical vacuum crushers, two-stage decanter and carton filter.

A custom-built structure that combines the traditional processes of olive cultivation and harvesting with an innovative, state-of-the-art system for extracting extra virgin olive oil, allowing all processing phases to be managed directly on the farm.

Manufacturing process

After harvesting in the field, the olives are placed in small ventilated boxes that do not allow fermentation processes.

The olives are then transported to the oil mill and processed within a few hours of harvesting.

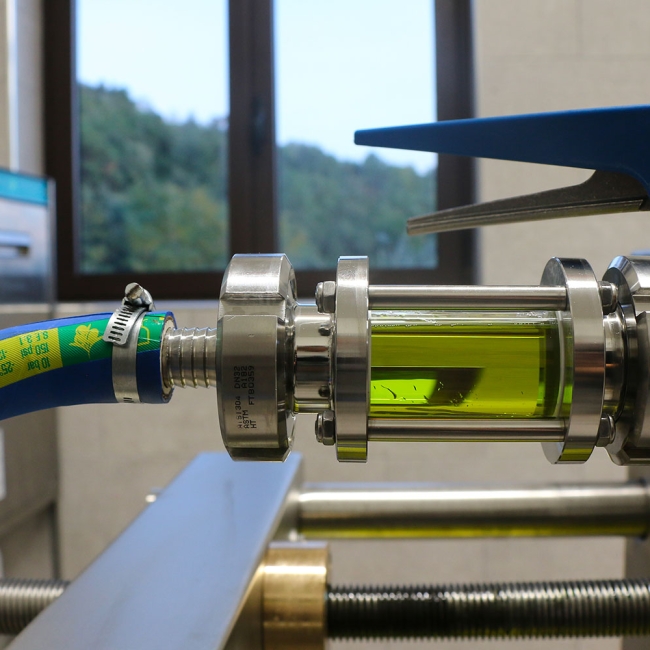

After washing and crushing, the resulting paste is graded under vacuum and in the shortest possible time, depending on the cultivars present, then immediately pushed into the decanter. The oil is extracted using a two-stage decanter, which means that no additional water is used, only the olive’s vegetation water is used.